Group 1160

Solidification of eutectic alloys

under

microgravity

Experiment Analysis

Preliminary Report

The experiment group:

Erkki Anttila

Mikko Suominen

Juha Tuisku

Kimmo Vänni

Endorsing Professor:

Professor Toivo Lepistö

Supervisor:

Professor Veli-Tapani Kuokkala

1. Analysis of the samples

We have planned the following microstructural studies and property measurements for the analysis and comparison of the samples prepared in microgravity and normal gravity conditions:

- identification of phases in the samples (XRD, electron diffraction)

- distribution, size and morphology of the a and b phases in the eutectic alloys (optical microscopy, SEM, TEM)

- distribution of elements in the samples (SEM/EDS, TEM/EDS)

- electrical conductivity

- thermal conductivity

The microstructural studies and property measurements are time consuming due to the required special specimen preparation procedures and the use of advanced equipment and techniques in the measurements and in the analysis of the results. Therefore, only preliminary results can be reported at this point. The test materials prepared during the microgravity flights seem to be, however, of high quality and therefore deserve carefull analysis with a wide variety of experimental techniques to reveal the possible deviations of the microstructure and properties of the microgravity samples from those of ordinary samples prepared in normal gravity conditions.

2. Preliminary results

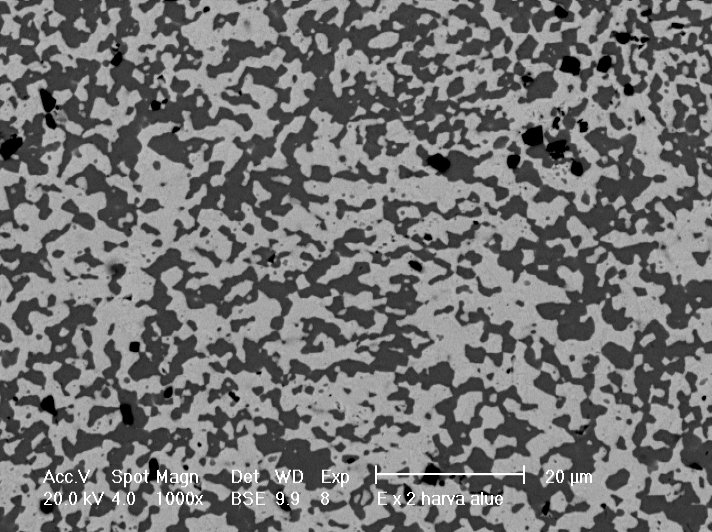

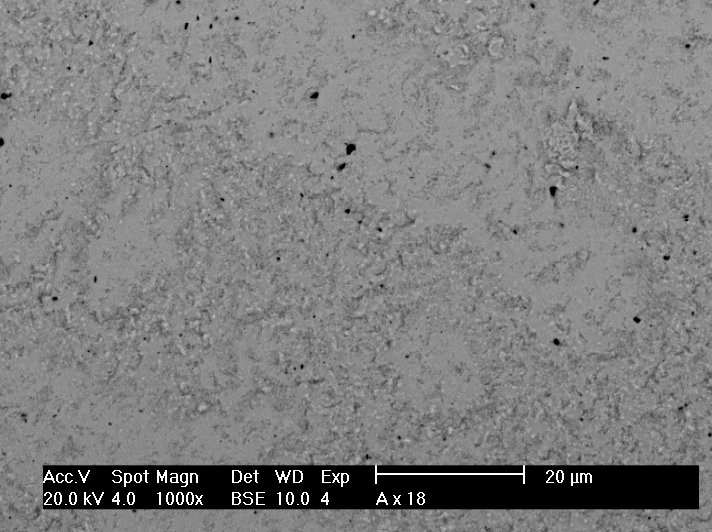

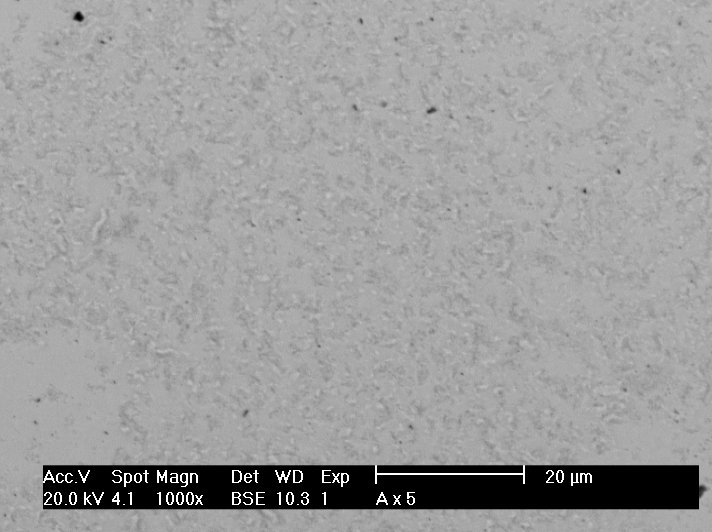

Two samples of two different eutectic alloys were examined using scanning electron microscopy (SEM) in back scatter electron (BSE) mode and EDS analysis. Figure 1 shows, as an example, the microstructure of an ordinary Sn63Pb37 eutectic solder alloy produced in microgravity. The superficial comparison with the corresponding microstructure produced in normal gravity did not reveal any immediate differences in these two samples. The corresponding pair of samples from SnAg3.5Cu0.7 lead-free solder, however, seem to show a clear difference in the distribution of the a and b phases, as seen in Figs. 2 and 3. This observation is, however, only very preliminary and based on one sample of each type only, and therefore needs more careful analysis. It can be anticipated that the possible differences will be in the fine structure of the microstructures and can be reliably revealed only by a careful comparison of the microstructures using advanced research techniques on several samples produced in both conditions. The preliminary results, however, seem promising and suggest that such differences can indeed be found.

Fig. 1. Tin-lead alloy produced in microgravity.

Fig. 2. Lead-free solder produced in normal conditions.

Fig. 3. Lead-free solder produced in microgravity conditions.

3. Further studies

The effect of gravity on the solidification of metallic alloys is a known fact and therefore differences in the microstructures produced at different gravity conditions can be expected. During the campaign our main goal was to demonstrate the feasibility of the solidification technique by which samples of various alloys can be easily melted and re-solidified during the short microgravity periods. To study also the effects of solidification rate (e.g. after considerable superheating) on the forming microstructure, our testing system was equipped with a compressed air cooling system but unfortunately, for safety reasons, its use during the flight was prohibited. By an improved design, however, these tests can be safely conducted in the coming flights provided that our project will be accepted for the second round. Also tests using high magnetic fields are included in the future research plan. The currrent state of our research project can be reviewed at